Enhanced Facility Disinfection Program

Vanguard Cleaning Systems | Four Step Process

Every Customer. Every Day. Every Time.

Vanguard Cleaning Systems of Minnesota Enhanced Disinfection Program combines infection control strategies through integrated CDC recommended procedures, EPA-Approved disinfectants, and OSHA bio-hazard disposal processes.

Step 1: Pre-Planning

TO ensure successful disinfection for a healthy facility, we first survey the customer’s facility to determine traffic flow and activity patterns. We focus on high traffic and high touch areas.

Step 2: Determine Scope of Work and Method

The scope of work will include the frequency of disinfecting, which areas will be disinfected, which method (Touch Point Disinfection and/or Disinfection Spraying) will be used and which EPA approved chemical(s) are correct for the surfaced being disinfected.

Step 3: Disinfection

Pre-clean of the surface to remove dirt. For high touch point surfaces, spray with an EPA approved disinfectant. Allow disinfectant to REMAIN WET for required dwell time (up to 10 minutes). Wipe area to prevent damage to surface. For large areas (manufacturing plant floors, gyms, restrooms, auditoriums), soft surfaces (wall dividers, chairs) or quick turnovers (classrooms, church services, bus/transportation) use air or electrostatic sprayers.

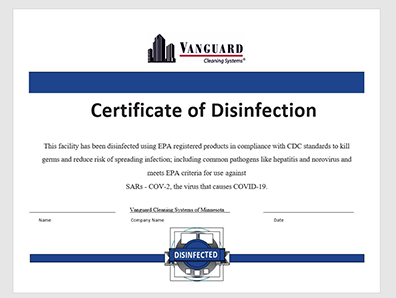

Step 4: Documentation of Tasks Performed

Once completed, you will receive a Certificate of Disinfection, optional Table tents and cards and signage for entrances. Utilizing these communications materials will help address fears that team members may have about the safety and cleanliness of the building. They will also help build confindence and trust that the right things are being done to insure a healthy workplace.